MAIN FEATURES

1. Used for connection of aluminum window door at 90 degree angle, with a maximum punching riveting height of 160mm.

2. Using PLC to ensure the stability and reliability.

3. Imported hydraulic system, powerful and stable.

4. The sunken multi-combination positioning system ensures positioning accuracy and facilitates the entry and exit of window frames.

5. The auxiliary positioning front and rear moving position is displayed digitally, the size is intuitive and easy to read, and the adjustment is convenient

TECHNICAL PARAMETERS OF ALUMINIUM WINDOW MAKING MACHINE FOR SALE

| Product Name | Aluminum Profile Corner Assembling Machine |

| Model | LZJ05-180 |

| Working Air Pressure | 0.5 -0.8 Mpa |

| Power Supply | 220V /380V / 415V 50 /60Hz (Customized) |

| Input Power | 3kw |

| Capacity of Oil Box | 50L |

| Hydraulic Pressure | 50 KN |

| Rated Oil Pressure | 15 Mpa |

| Profile Height | 160 mm |

| Brand | IGM |

| Operation Manual | √ |

| Operation Video | √ |

| Color Customization | √ |

| MOQ | 1 SET |

| Overall Size | 1200*1200*1250 mm |

DETAILS

The maximum processing height is 180 mm, which is suitable for large-sized aluminum door and window profiles.

The cornering effect is perfect, flat and without misalignment. The hydraulic pressure combined with the PLC program makes the feeding four-part stable.

Control panel of aluminium window making machine for sale, buttons are from Schneider brand.

Specialized PLC program, low voltage electrical appliances come from Schneider.

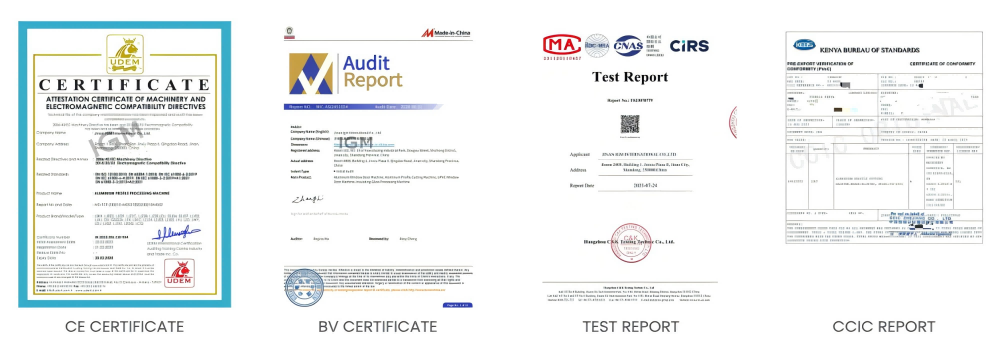

OUR CERTIFICATES

Our UPVC window machine , aluminum window machine have passed CE certification and BV certification, as well as third-party safety and environmental protection reports. We are able to provide customers with safe, efficient and stable products.

PACKING AND SHIPPING

LCL: aluminium window making machine for sale is packed in fumigation-free plywood, the pallet is thickened and raised, and the machine base is fixed with steel wire.

FCL: Generally, the outer packaging is plastic film, and the machine is fixed in a 20/40-foot container with steel wire or special packaging tape; the outer packaging can also be selected as a fumigation-free wooden box according to requirements. Extra-high-size machines require open-top cabinets.

We have many years of export and loading experience. While ensuring the safety of the machines, we rationally plan and utilize container space to save transportation costs for our customers.

OUR ADVANTAGES

1. Technical capability and innovation capability:

IGM has a senior R&D and design team with 15-20 years of industry experience; the company's annual R&D cost accounts for about 10%-15% of its profits, and it launches an industry-leading product every one to two years; it has numerous invention patents and utility model patents, and the number and technical level belong to the first echelon in China.

2. Ultimate product quality and reliability:

Our factory has passed international quality certification systems such as ISO and BV. The equipment has a low failure rate and a long service life. The market is very satisfied with product quality and customer satisfaction surveys.

3. High production capacity and efficiency:

The factory covers an area of 15,000 square meters, has its own machining workshop and sheet metal processing workshop; has more than 80 employees; ERP management has been implemented from procurement, finance, orders, production, and delivery, with a high degree of optimization of production processes, high production efficiency, and reduced production costs.

4. Market share and brand influence:

Market coverage: market share and distribution at home and abroad.

Brand awareness and reputation: brand awareness, reputation and customer loyalty within and outside the industry.

Sales network and service network: the breadth of sales channels and the coverage of after-sales services.

5. Customer customization capabilities:

Provide customized solutions based on customer needs; respond faster to customer needs and market changes.

OUR SERVICES

Installation and commissioning services:

On-site installation support: Provide professional technicians to install equipment on-site.

Equipment commissioning: Ensure that the equipment can operate normally after installation, including commissioning and testing.

Technical training:

Operation training: Provide equipment operation training to customers' operators to ensure that they can use the equipment correctly and safely.

Maintenance training: Provide equipment maintenance and maintenance training to customers' maintenance personnel to improve the service life and reliability of equipment.

Maintenance and maintenance:

Regular inspection: Provide regular equipment inspection services to discover and solve potential problems and prevent failures.

Preventive maintenance: Provide preventive maintenance suggestions and services based on the use and characteristics of the equipment.

Maintenance services:

Quick response: Establish a quick response mechanism to handle customer maintenance requests in a timely manner.

Remote support: Provide remote technical support through telephone, video and other means to solve equipment failures.

Spare parts supply: Ensure the timely supply of spare parts and reduce downtime caused by spare parts shortages.

Technical support and consulting:

24/7 support: Provide round-the-clock technical support and consulting services to answer customer questions at any time.

Provide technical information, FAQs and real-time consultation.

Warranty service:

Warranty period: longer warranty time - 18 months, provide lifelong after-sales service.

Customer feedback and improvement:

Regularly contact customers to actively understand the use of equipment and customer satisfaction.

Attach importance to customer feedback and continuously improve products and services based on customer suggestions.

Upgrade and transformation service:

According to technological development and customer needs, provide equipment upgrade services to improve equipment performance.

Provide customers with equipment transformation solutions to meet special process requirements or improve production efficiency.