TECHNICAL PARAMETERS

| Model | SKZX-A3-CNC-1200 |

| Working Air Pressure | 0.5 -0.8 Mpa |

| Electric Power | 220V /380V / 415V 50 /60Hz |

| Process Length | 1200mm |

| Process Width | 150 mm |

| Process Height | 150 mm |

| Process Angles | 90° , 0° ,-90° |

| Diameter of Mill Cutter | ∅ 8mm /10mm |

| Machine Size | 2000*1300*1800mm |

| Gross Weight | 1000 KGS |

| Brand | IGM |

| Operation Manual | √ |

| Operation Video | √ |

| Color Customization | √ |

| MOQ | 1 SET |

MAIN FEATURES

1. Used for milling various hole types of aluminum doors and windows, UPVC doors and windows, including but not limited to lock holes, handle holes, drainage holes, mounting holes, etc.

2. The workbench can be flipped on three sides at 90, 0, -90 degrees.

3. Multiple holes can be processed on the same surface.

4. Select the graphics, enter the size and coordinate position, and the operation is simple.

5. Adopt servo motor for precise control.

6. High-power spindle motor, maximum speed of 24,000 rpm, low noise, good milling effect.

7. Extended sizing table, can process long-size profiles.

8. It can mill two or three layers according to the profile, with high efficiency.

9. The feed speed and milling speed can be set separately, suitable for different profiles.

10. Automatic oiling system for guide rails.

11. The language support translation of the operating system, such as Spanish, Russian, French, etc.

DETAILS OF ALUMINIUM WINDOW MAKING MACHINE

The high-speed spindle has a maximum speed of 24,000 rpm, is stable, has low noise, and produces smooth milling holes.

Precision guide rails and gear racks have high repeatability and long service life.

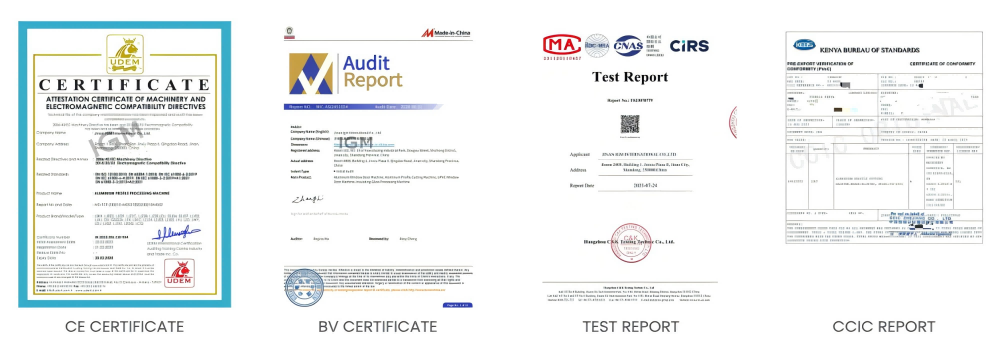

OUR CERTIFICATES

Our UPVC window machine , aluminium window making machine have passed CE certification and BV certification, as well as third-party safety and environmental protection reports. We are able to provide customers with safe, efficient and stable products.

OUR ADVANTAGES

1. Technical capability and innovation capability:

IGM has a senior R&D and design team with 15-20 years of industry experience; the company's annual R&D cost accounts for about 10%-15% of its profits, and it launches an industry-leading product every one to two years; it has numerous invention patents and utility model patents, and the number and technical level belong to the first echelon in China.

2. Ultimate product quality and reliability:

Our factory has passed international quality certification systems such as ISO and BV. The equipment has a low failure rate and a long service life. The market is very satisfied with product quality and customer satisfaction surveys.

3. High production capacity and efficiency:

The factory covers an area of 15,000 square meters, has its own machining workshop and sheet metal processing workshop; has more than 80 employees; ERP management has been implemented from procurement, finance, orders, production, and delivery, with a high degree of optimization of production processes, high production efficiency, and reduced production costs.

4. Market share and brand influence:

Market coverage: market share and distribution at home and abroad.

Brand awareness and reputation: brand awareness, reputation and customer loyalty within and outside the industry.

Sales network and service network: the breadth of sales channels and the coverage of after-sales services.

5. Customer customization capabilities:

Provide customized solutions based on customer needs; respond faster to customer needs and market changes.

OUR SERVICES FOR ALUMINIUM WINDOW MAKING MACHINE

Installation and commissioning services:

On-site installation support: Provide professional technicians to install equipment on-site.

Equipment commissioning: Ensure that the equipment can operate normally after installation, including commissioning and testing.

Technical training:

Operation training: Provide equipment operation training to customers' operators to ensure that they can use the equipment correctly and safely.

Maintenance training: Provide equipment maintenance and maintenance training to customers' maintenance personnel to improve the service life and reliability of equipment.

Maintenance and maintenance:

Regular inspection: Provide regular equipment inspection services to discover and solve potential problems and prevent failures.

Preventive maintenance: Provide preventive maintenance suggestions and services based on the use and characteristics of the equipment.

Maintenance services:

Quick response: Establish a quick response mechanism to handle customer maintenance requests in a timely manner.

Remote support: Provide remote technical support through telephone, video and other means to solve equipment failures.

Spare parts supply: Ensure the timely supply of spare parts and reduce downtime caused by spare parts shortages.

Technical support and consulting:

24/7 support: Provide round-the-clock technical support and consulting services to answer customer questions at any time.

Provide technical information, FAQs and real-time consultation.

Warranty service:

Warranty period: longer warranty time - 18 months, provide lifelong after-sales service.

Customer feedback and improvement:

Regularly contact customers to actively understand the use of equipment and customer satisfaction.

Attach importance to customer feedback and continuously improve products and services based on customer suggestions.

Upgrade and transformation service:

According to technological development and customer needs, provide equipment upgrade services to improve equipment performance.

Provide customers with equipment transformation solutions to meet special process requirements or improve production efficiency.